Emirates Financial Towers, 1191 Spaces

DUBAI, UAE

Robotic Parking System was contracted for the design and build of this 1,191 space automated parking facility. The system design was inserted between the concrete structure of the above towers. The facility includes an integrated automatic car wash.

All of the machinery for the Emirates Financial Towers was manufactured at our 100,000+ sq ft. factory in Clearwater, FL. Once the machinery’s automation components were programmed, the machinery was vigorously tested before being shipped to Dubai.

The Robotic Parking System technology is patented in the US, China, India, Russia and other countries. Additional patents are pending in the UAE and numerous countries throughout the world.

Following the completion of the historic automatic car park system of EFT, Robotic Parking Systems went on to build an even larger facility in Kuwait. The fully automated system housed at the Al Jahra Court Complex holds the current Guinness World Record for largest fully automated parking facility.

Developer: ENSHAA & MAG, Dubai | Architect: Al Gurg Architects | Year Completed: 2011 | Operations & Maintenance: Not by RPS

Property Type

Mixed Use

Parking Levels

+5,-4 (9 levels)

Parking Spaces

1194

Peak Capacity

340-360 cars/hr

IMPLEMENTATION

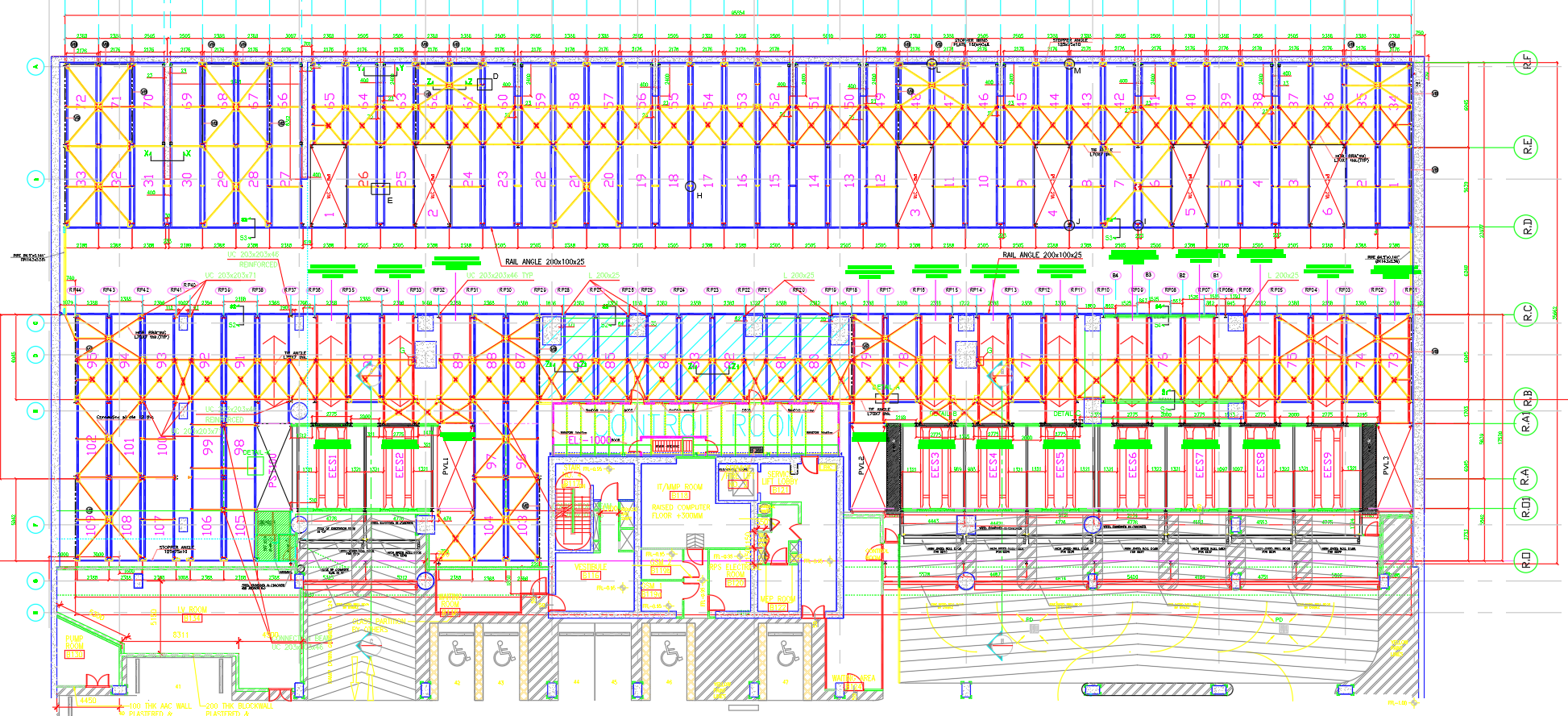

The Emirates Financial Towers (EFT) in Dubai feature the world’s second largest automated parking system, accommodating 1,194 vehicles. Ingeniously integrated into the basement beneath the twin towers, the garage was designed without disturbing the architectural vision or structural layout. A slightly customized RPS 1000 system was adopted to fit the unique requirements of the complex.

With nine entry/exit stations accessed via internal ramps, the system ensures seamless, contactless parking and retrieval, replacing inefficiencies of conventional garages. It was purposely chosen over a six-level ramp-style garage that would have provided about 1,250 traditional spaces but consumed more land, time, and cost. Instead, the automated approach delivered over 50% land savings, while also satisfying the uniform concourse height requirement across all DIFC buildings.

In doing so, EFT gained a space-efficient, future-ready solution that maximized leasable area and reinforced its status as a landmark in both technology and design.

INNOVATION

Robotic Parking Systems implemented the best possible engineering strategy to design and install one of the world’s largest automated parking facilities at the Emirates Financial Towers. In record time, the project delivered approximately 1,800 tons of structural steel, 840 tons of pallets, and nearly 100 robotic machines, all seamlessly integrated into the towers’ basement without disturbing their architectural or structural layout.

The challenge was formidable: architects were strictly limited by the concourse-level height requirements of the Dubai International Financial Centre (DIFC), while conventional ramps and driveways would have consumed nearly 30% of the land area. Under such constraints, building a traditional ramp-style parking garage was simply impossible. Instead, Robotic Parking Systems worked hand-in-hand with the project’s architects, optimizing every inch of space to create an innovative solution that preserved both the structural integrity and the architectural elegance of the towers.

Equally critical was the financial dimension. In a prime financial district where land values are extremely high, every square foot matters. The automated system offered a cost-competitive solution, freeing up valuable leasable space and ensuring maximum economic return for the development.

The resulting garage extends to nine underground levels, reaching a depth of 20 meters below grade. Achieving the same capacity with a conventional concrete garage would have required a depth of nearly 38 meters, which was both cost-prohibitive and technically unfeasible due to high water tables and increasing soil pressure with depth. Moreover, a 20-meter-deep concrete garage would have reduced the Gross Floor Area (GFA) by about 40% because it could not accommodate the required number of spaces.

By contrast, the Robotic Parking System provided the full required capacity within half the depth, preserving GFA, cutting costs, and solving technical challenges that traditional methods could not overcome. This project stands as a benchmark of innovation, showcasing how advanced automation, smart engineering, and close collaboration with architects can transform urban infrastructure in some of the world’s most demanding environments.