In the world of commercial real estate development, parking requirements often feel like a necessary evil. Fitting large, unattractive concrete parking structures into a project can be an aesthetic and logistical headache, especially in dense urban environments. But the need for parking isn’t going anywhere; so intelligent, space-saving solutions with an eye on ROI are more necessary than ever.

Albert Einstein once said, “In the middle of difficulty lies opportunity.” Robotic Parking Systems, an advanced alternative to conventional garages, offers a huge opportunity in today’s landscape.

Developed over 30 years ago, Robotic Parking Systems with its patented pallet and vehicle transport system is now perfectly situated to deliver what today’s commercial real estate developers need: land efficient parking fully equipped for modern transportation technology such as electric and driverless vehicles.

Like airplanes and personal computers, the path from invention to mass adoption takes time. But today, with mounting urban density, rising land costs, and the push for greener, smarter infrastructure, the timing couldn’t be better.

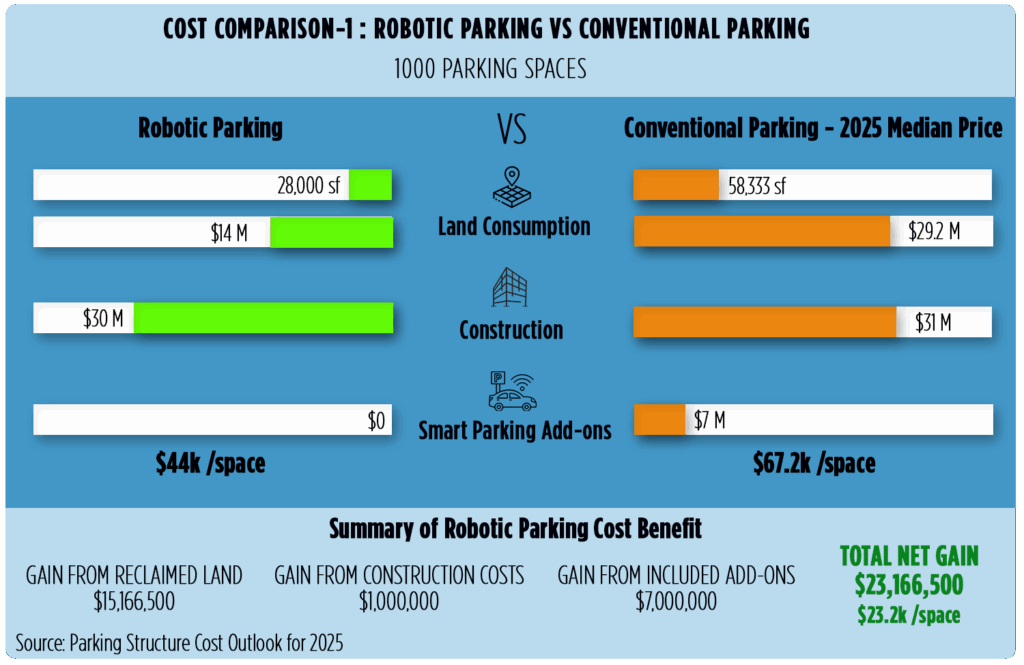

So how do Robotic Parking Systems compare to traditional concrete garages? Here is the breakdown into three critical factors.

Key Factor 1: Land Consumption

Space is the most valuable asset in real estate, particularly in cities where every square foot of land carries a huge price tag. It is well recognized that traditional concrete parking garages are inefficient, consuming large amounts of land to accommodate ramps, drive aisles, turning radii and people moving into and out of cars.

CONVENTIONAL CONCRETE PARKING

- 1,000 spaces x 350 sf/space = 350,000 sf total structure size

- Divided over 6 levels = 58,333 sf of land required

ROBOTIC PARKING SYSTEM

- 1,000 spaces fit on a 100 ft x 280 ft footprint = 28,000 sf of land required

RECLAIMED LAND:

58,333 sf – 28,000 sf = 30,333 sf of land reclaimed

If that reclaimed land can be developed or sold at $500 per square foot, the gain is substantial:

30,333 sf x $500 = $15,166,500 in additional asset value

In premium urban areas, this land value can be even higher. According to loopnet.com, in New York City, land prices frequently exceed $1,000 to $2,000 per sf; in Los Angeles, over $1,700 per sf in top neighborhoods; and in Tampa, average land costs hover around $300 per sf, with premium zones reaching $700+ per sf. That same 30,000 sf could yield $20 million or more in added value, depending on location.

Key Factor 2: Construction Costs

In urban areas, the cost of structured concrete parking garages varies widely with cost per space estimates ranging from $15,000 to $70,000 per space. In general, the cost of each space in a Robotic Parking System is $30,000.

According to WGI’s Parking Structure Cost Outlook for 2025 white paper, the median construction cost per space in the US this year is $31,000. This price does not include soft costs such as required automatic fire sprinkler systems which increases the cost per space by an additional 15% to 25%. With a Robotic Parking System, these soft costs are built in to the $30,000 price.

In the comparison below, we are using conservative numbers. In this scenario, Robotic Parking Systems involve higher up-front construction costs compared to traditional concrete garages. However, even here, the long-term ROI more than offsets this initial investment, especially when viewed through a land-use and opportunity-cost lens.

COMPARISON 1: CONVENTIONAL CONCRETE GARAGE USING 2025 MEDIAN PRICE

- 1,000 spaces x $31,000 per space = $31,000,000 total construction cost

ROBOTIC PARKING SYSTEM

- 1,000 spaces x $30,000 per space = $30,000,000 total construction cost

NET GAIN IN CONSTRUCTION COSTS: $1,000,000

GAIN FROM RECLAIMED LAND: $15,166,500

TOTAL NET GAIN: $16,166,500 (without the Smart Parking Add-ons included)

COMPARISON 2: CONVENTIONAL CONCRETE GARAGE USING CONSERVATIVE PRICE

- 1,000 spaces x $20,000 per space = $20,000,000 total construction cost

ROBOTIC PARKING SYSTEM

- 1,000 spaces x $30,000 per space = $30,000,000 total construction cost

NET DIFFERENCE IN CONSTRUCTION COSTS: –$10,000,000

GAIN FROM RECLAIMED LAND: $15,166,500

TOTAL NET GAIN: $5,166,500 (without the Smart Parking Add-ons included)

It is important to note that even when doing a cost comparison of Robotic Parking vs Conventional Concrete Parking to consider reclaimed land along with the construction costs. When one takes into consideration the $15M+ gain in usable land and the reduction in operational costs, the robotic system is clearly the better long-term investment. And again, this is using the incredibly conservative and generous number of $20,000 for each space in the concrete garage.

Key Factor 3: Opportunity Advantage

Perhaps the most compelling value proposition is this: by using a Robotic Parking System for this 1000 space garage, the developer creates 30,000+ square feet of usable land that would otherwise be tied up in ramps and void space.

This unlocked space can be transformed into revenue-generating commercial, residential, or retail square footage, drive new sources of income and increase the overall value of the development.

Even in a modest market, this opportunity can conservatively be valued at $5,000,000 or more, depending on how the space is repurposed.

Additional Built-In Benefits

Robotic Parking Systems don’t just save space, they integrate features that would require substantial additional investment in a concrete garage, including:

- Revenue & Access Control System

- Wayfinding Installation

- Security Systems

- Enclosed Façade and Roofing

- Fire Suppression Systems

- EV Charging Infrastructure

- Electric Installation with Generator

- Online Reservation System

- Readiness for Autonomous Vehicles

The cost of installing these features in a 1,000-space conventional garage is estimated at $7,000,000. With a Robotic Parking System, these are built in, offering both cost savings and operational efficiency from day one.

Lower Operating Expenses and Sustainability Gains

Robotic Parking Systems also yield long-term operational cost reductions. Since there’s no need for cars to run inside the facility, there is no exhaust ventilation system required. Lighting, security staffing, and maintenance costs are also lower due to the enclosed and automated environment.

Robotic Parking Systems can contribute toward LEED certification and align with sustainability goals which are a growing priority for both developers and municipalities.

Smarter Parking for Smarter Cities

Robotic Parking Systems are no longer a futuristic concept, they’re a financially and environmentally intelligent solution that meets modern demands of urban development.

With millions in land savings, built-in infrastructure, and a clear ROI advantage, it’s time for developers and architects alike to consider moving beyond the traditional ramp garage. For developers looking to maximize both space and return, Robotic Parking is not just an alternative, it’s a competitive edge.

See for yourself how a Robotic Parking System fits into your development plans. Speak to Robotic Parking Systems’ experts and receive an initial set of drawings at no cost or obligation for your parking project by clicking on the link below.